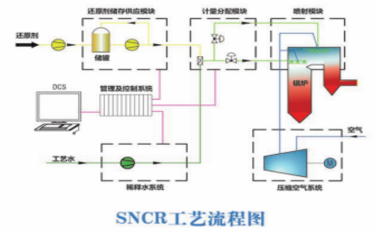

Process Introduction

SNCR (Selective Non Catalytic Reduction) denitration process is to inject a reducing agent into the flue gas region at 800~1100 ℃. Without the need for a catalyst, NOx in the flue gas is selectively reduced to N2 and H2O. The commonly used reducing agents are generally liquid ammonia, ammonia water, urea, etc.

Process Principle

4NO+4NH3+O2→4N2+6H2O

6NO2+8NH3→7N2+12H2O

Technical Advantages

2. The impact of SNCR process on boiler efficiency is less than 0.5%, and the device availability is 98%

3. Improve the overall performance of denitrification by optimizing the flow field design, and scientifically and reasonably configure the number and position of spray guns

4. Using a reducing agent dilution control system, the injection amount and concentration of each spray gun can be effectively adjusted

Improve the utilization rate of reducing agent and reduce the ammonia escape concentration while ensuring the removal efficiency