Process Introduction

If NOx in industrial waste gas is directly discharged into the atmosphere, it will cause serious pollution to the environment. Our company combines the characteristics of domestic flue gas denitrification with advanced foreign technologies, cooperates with KURABO Company of Japan and research groups of well-known universities in China, and can provide customers with a complete set of mature denitrification technologies, including medium temperature SCR process, low temperature SCR process, SNCR process, SCR+SNCR and other denitrification technology processes, and combines them with ozone denitrification process, Forming a new process with distinctive denitration technology.

Process Principle

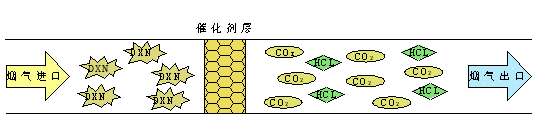

Process schematic diagram:

Reaction mechanism of NOx removal:

4NO+4NH3+O2→4N2+6H2O

6NO2+8NH3→7N2+12H2O

Reaction mechanism of dioxin removal:

C12H4O2CL4+11O2→12CO2+4HCL

C12H4O2CL4+23/2O2→12CO2+4HCL

Technical Advantages

1. Mature technology, stable operation, high NOx removal efficiency, up to 95%

2. SO2/SO3 conversion rate < 1%, effectively reducing the generation of ammonia hydrogen sulfate

3. Assists in the removal of dioxins and heavy metals from flue gas