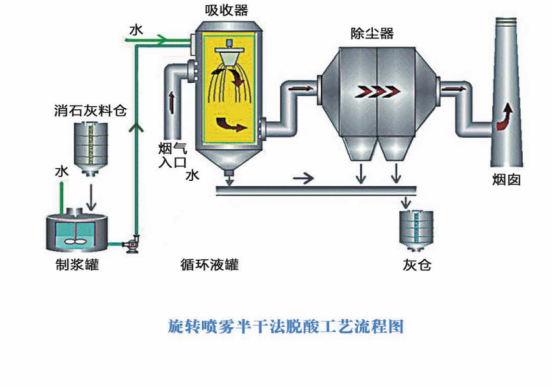

Process Introduction

The rotary spray semi dry deacidification technology is to spray the absorbent slurry Ca (OH) 2 in the reaction tower. The droplets are evaporated by the hot flue gas while absorbing SO2 in the flue gas, and the generated solids are captured by the dust collector. Rotary spray semi dry deacidification technology is widely used in waste incineration industry.

Process Principle

Rotary spray semi dry deacidification system includes: desulfurizer storage, transportation and slurry preparation supply system, deacidification reaction system, ash discharge system, activated carbon injection system, auxiliary system, electric control system, etc.

Technical Advantages

1. Large operating flexibility, fast response to different flue gas flows, temperatures, and components

2. The droplet particles are very small and have a large specific surface area. They can react quickly with acidic gases, and can simultaneously generate gas-liquid and gas-solid two-phase reactions. The reaction efficiency is high and the absorption is relatively thorough

3. The process has low water consumption, does not generate wastewater, and can use and consume low quality water

4. The system is widely used in the waste incineration power generation industry due to its simple operation, rapid response, and high reliability