Process Introduction

Process Principle

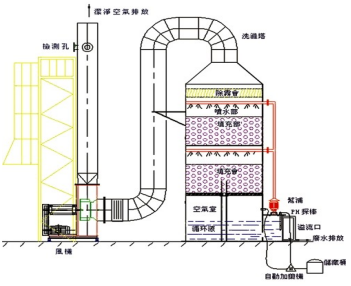

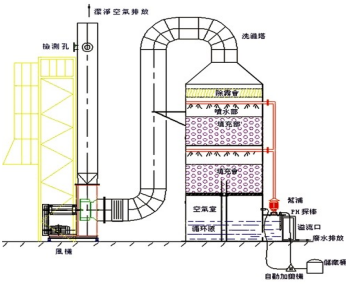

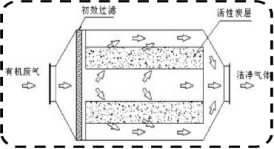

Washing and absorption: A countercurrent packed absorption tower is used. When the gas passes through the tower, it fully contacts and mixes with continuously circulating acidic and alkaline washing liquids, respectively absorbing alkaline and acidic gases in the flue gas, including ammonia, amines, hydrogen sulfide, and low-level fatty acids.

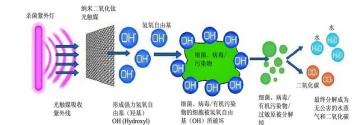

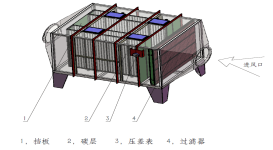

UV photolysis: UV photolysis catalytic oxidation waste gas purification equipment is a mature process that activates nano catalysts (TiO2) through ultraviolet radiation of a specific wavelength, generating electron hole pairs, allowing the photocatalyst to interact with H2O molecules and O2 molecules, combining to generate hydroxyl radicals (· OH), which are used to decompose harmful component molecules, thereby achieving the goal of deodorization and eliminating air pollution.

Technical Advantages

1. High processing efficiency

2. Comprehensive functions, good absorption effect

3. Stable system operation and low operating cost

Performance Index

Efficiency can reach over 90%